Scanning

We offer aluminium mirrors for scanning systems between 1 and 11 microns.

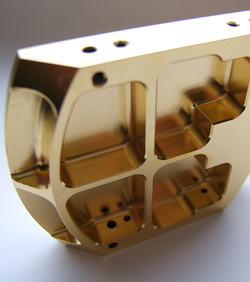

Aluminium is an excellent alternative to silicon because it can be machined into complex shapes and chemically polished to an exceptionally smooth finish.

It is also possible to make aluminium mirrors lighter by using ribbed designs on the rear surfaces, like those seen on most silicon carbide scanner mirrors.

Our mirrors have an improved resistance to laser damage due to the layer of electroless nickel that we deposit between the metal and the coating. This amorphous layer also reduces unwanted scatter and protects the mirror from oxidisation.

We also offer diamond machining of polygons for scanning applications. Talk to us about your specific requirements and specifications.

Contact us for more information on SCANNING MIRRORS AND POLYGONS

We can offer technical support to assist in the best design for our customers’ applications. Our solutions include mirrors for use in galvanometer and polygon systems. Alternatively, we can manufacture mirrors to technical drawings provided by the customer.

LBP Optics offer several coatings for use on our aluminium scanner mirrors:

- Electroplated Gold, for near and far infrared use.

- MaxR for 9.27 to 10.6 microns, high reflectivity for CO2 lasers.

- Protected silver for visible and near infrared use.

- A simple MgF2 overcoat