Uses of copper mirrors

Well known as the material of choice for CO2 industrial laser mirrors, copper mirrors are used in laser metal cutting, laser engraving, and laser welding. Many other infrared applications can also use copper mirrors and they are the most common laser mirror type for high energy and broadband infrared applications.

Because polished copper reflector surfaces react with the atmosphere and lose reflectivity, most, but not all cavity mirrors and beam delivery mirrors are generally used with a coating to improve reflectivity, durability, or alter polarisation on reflection.

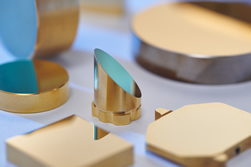

We offer several metal mirror optical coatings:

- Electroplated gold coated copper mirrors.

- MaxR zero phase shift copper mirrors for CO2 laser.

- L/4 reflective phase retarder mirror for CO2 laser.

- Protected silver coating for broad infrared reflectivity.

“We received the mirror and are happy with it. It arrived in perfect condition and is being used."

M J - University of Nottingham

Benefits of copper mirrors

When freshly polished, uncoated copper mirror surfaces have high natural reflectivity in the infrared, high thermal conductivity and a high heat capacity.

Copper is a crystalline metal, and its surface quality and laser damage resistance is limited by the micro crystallinity of the reflective surface. To improve the laser damage resistance and reduce scatter, our copper mirrors have a thin intermediate layer of electroless nickel deposited. Electroless nickel is an amorphous (glass like), non-crystalline material that can be polished to an exceptional smoothness. Electroless nickel plating also protects the whole of the mirror from oxidation and prevents contamination or reaction of exposed copper with the lasing gas such as in sealed slab discharge resonators.

LBP Optics' copper mirrors are chemically polished and the surfaces are super smooth and free of imperfections from turning lines, fly cutting arcs and diffractive patterns. This gives a much higher laser induced damage threshold and a low scatter mirror surface suitable for use in the visible and UV.

Finally, our proprietary stress relieving and heat treatment gives long term stability and performance, across a wide range of operating temperatures.

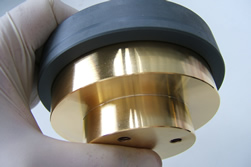

For the highest laser powers and for maximum stability, sealed internal water cooling channels can be machined into the copper mirror itself.

Mirror types

As copper is readily machinable, we offer a huge range of mirror shapes and sizes such as prisms, axicons, rectangular or square mirrors, chopper wheels, knife edge mirrors and shutter mirrors. By engineering in features such as dowel holes, tapped and helicoiled holes and flanges, a well-designed copper mirror can reduce costs for OEMs in mounting, assembly and laser alignment.

LBP Optics stock a wide range of copper mirrors with a selection of mirror coatings that are standard replacement parts for the most popular CO2 laser cutting systems. Whilst meeting or exceeding the OEM standards, these also cost less, as we are an optical manufacturer. We can offer replacement copper mirrors for most laser cutting & laser engraving systems.

Mirror repair and refurbishment

Used CO2 laser optics can often be reworked to as good as new condition, a service used by a growing number of our customers. The raw metal material in larger mirrors, water cooled mirrors or laser mirrors with complex engineering can be a large part of the cost of the optic, so refurbishment makes economic, technical and environmental sense - contributing to ISO 14000.

.jpg)